Technical data OptiFlex Pro models

|  |  |  |

| Electrical data | OptiFlex ® Pro B | OptiFlex ® Pro Q | OptiFlex ® Pro F | OptiFlex® Pro S |

| Nominal in put voltage | 100-240 VAC | 100-240 VAC | 100-240 VAC | 100-240 VAC |

| Frequency | 50-60 Hz | 50-60 Hz | 50-60 Hz | 50-60 Hz |

| Temperature range | 5°C to +40°C +41°F to +104°C | 5°C to +40°C +41°F to +104°C | 5°C to +40°C +41°F to +104°C | 5°C to +40°C +41°F to +104°C |

| Pneumatic data | ||||

| Max. manual unit input pressure Input presure OptiStar | 10 bar / 145 psi 5,5 bar / 80 psi | 10 bar / 145 psi 5,5 bar / 80 psi | 10 bar / 145 psi 5,5 bar / 80 psi | 10 bar / 145 psi 5,5 bar / 80 psi |

| Max. water vapor content of compressed air Max. oil vapor content of compressed air | 1,3 g/m³

0,1 mg/m³ | 1,3 g/m³

0,1 mg/m³ | 1,3 g/m³

0,1 mg/m³ | 1,3 g/m³

0,1 mg/m³ |

| Dimensions | ||||

| Compressed air consumption nomal operation | 5,5Nm³/h | 5,5Nm³/h (for a short time during cleaning cycle 30 Nm³/h | 7,5Nm³/h | 5,5Nm³/h |

| Hopper volume | – | – | 50l | 18l |

|  |  |

OptiSelect ®Pro Type GM04 | OptiStar® | OptiFlex ®Pro Manual Coating equipment |

| Approvals | ||

| 0102 II 2 D PTB 19 ATEX 5001 | 0102 II 3 (2) D PTB 19 ATEX 5001 | II 3 D IP54 120 °C |

|  |

OptiFlex ®Pro L | OptiFlex ®Pro W |

| For small batches | The universal solution |

| Do you carry out lab applications or quality tests? The OptiFlex Pro L unit is the pefect solution for lab use and quality control.

| For upgrades, to be mounted on booth walls or at your production site: OptiFlex Pro W can be integrated in any existing surrounding.

|

|  |

OptiFlex ®Pro C | OptiFlex ®Pro CF |

| For Lab use | For Lab use |

| Do you want to coat small batches or samples? Your solution is the OptiFlex Pro C with self-fluidizing application cup.

| Do you want to coat small batches or samples? Your solution is the OptiFlex Pro CF with funnel cup.

|

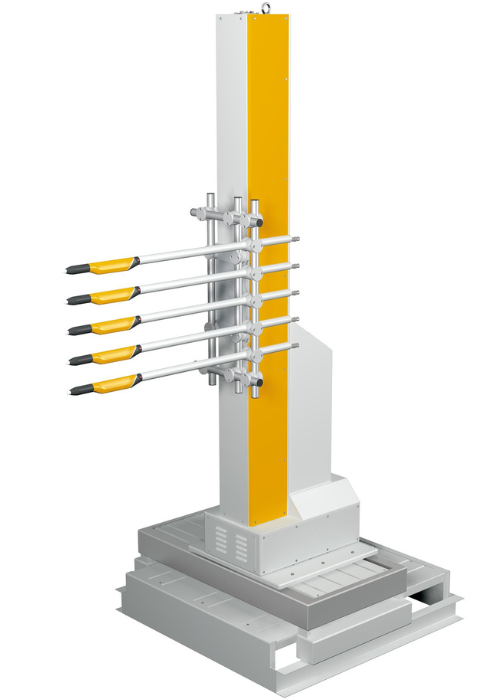

Technical data

| ZA07/08 | ZA15 | |

| Stroke speed | 0,01-0,6 m/s | 0,08-0,4 m/s | |

| Aceeleration | 0,1-2,0 m/s² | 0,1-1,5 m/s² | |

| Loading capacity | Max. 50kg | Max. 100kg | |

| Positioning system | Incremental encoder | ||

| Voltage | 230 V, 50/60 Hz | ||

| Temperature range | 10°C -+40°C | ||

| Zone definition | 3 D (ATEX Zone 22) | ||

| Motor type | Three-phase asynchronous motor | ||

| Power | 0,75 kW | ||

| Combination example with 3 axes | |||

| Reciprocator | 13 | 18 | 23 | 28 | 33 | 38 |

| ZA07/08 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| ZA15 | ✓ | ✓ | ✓ | ✓ | – | – |

| Total height (A) | 2.385 mm | 2.885 mm | 3.385 mm | 3.885 mm | 4.385 mm | 4.885 mm |

| Adjustable stroke (B) | 1.300 mm | 1.800 mm | 2.300 mm | 2.800 mm | 3.300 mm | 3.800 mm |

| Lower inflection point (C) | 326 mm | 326 mm | 326 mm | 326 mm | 326 mm | 326 mm |

Associated system componets

- MagicControl for ZA07 and ZA15

- OptiMove control unit for ZA08

- Automatic gun OptiGun GA03-X

| ||

| Stroke speed | 0,08-0,6 m/s | |

| Aceeleration | 0,1-2,0 m/s² | |

| Loading capacity | Max. 25kg | |

| Voltage | 230 V, 50/60 Hz | |

| Temperature range | 0°C up to +40°C | |

| Zone definition | 3 D (ATEX Zone 22) | |

| Synchronous motor | 400 watt degree of protection IP54 insulation class F | |

| Reciporocator ZA10 | |

| Total height (A) | 2760 mm |

| Adjustable stroke (B) | 1800 mm |

| Lower reversing point (C) | 265 mm |

Mounting Versions

- XT03 manual trolley

- Direct Fixation on concrete floor (with plugs)

| OptiMove CR09 axis control |

| |

OptiMove axis control |

Reviews

There are no reviews yet.