“Class A” Coating

Environmentally friendly

Transfer efficiency optimization

“Class A” Coating

Environmentally friendly

Transfer efficiency optimization

Why Choose Ransburg?

Ransburg, a brand under Carlisle Fluid Technologies, is a global leader in the design and manufacture of manual and automatic electrostatic spray equipment. As a pioneer in electrostatic spray technology for industrial, manufacturing, and top-tier automotive markets, Ransburg continuously refines the most efficient electrostatic spraying systems to deliver flawless Class A finishes for every customer product — all while minimizing VOC emissions and achieving outstanding transfer efficiency.

Harold Ransburg, the inventor of the electrostatic process, developed the first electrostatic application system in the 1940s with the introduction of the Ransburg No. 1 Indirect Charge Process. Over the years, backed by deep technical expertise, Ransburg has achieved material transfer efficiencies exceeding 97%, significantly reducing overspray and VOC emissions. The company was acquired by Carlisle Companies in 2015.

Today, Ransburg’s cutting-edge technology has led to the advancement of rotary atomizers and spray devices with exceptional atomization capabilities — many of which are now deployed in production facilities that demand high-quality finishes with superior transfer performance.

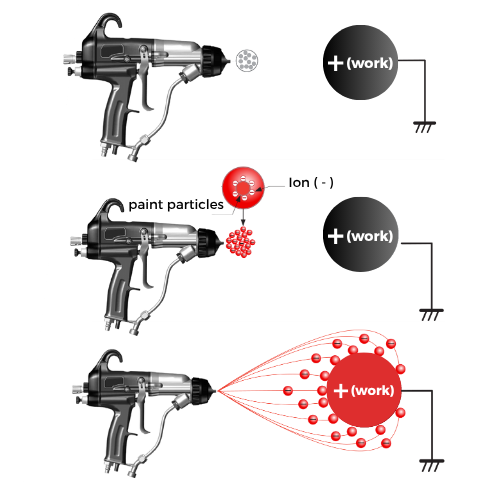

Leveraging electrostatic coating technology, an electric field is generated between a grounded workpiece (positive pole) and a spray device charged with high negative voltage (negative pole). Finely atomized paint particles, imbued with a negative charge, are drawn to the workpiece, adhering seamlessly to its surface. This innovative approach drastically cuts overspray, reducing paint usage (lowering costs), accelerating painting processes (boosting efficiency), and enhancing workplace safety while safeguarding the environment—delivering a groundbreaking solution for modern coating needs.

Maximize Transfer Efficiency and Reduce Operating Costs

High paint transfer efficiency means less paint waste and better adhesion to the surface of the workpiece. Thanks to optimized design and precise electrostatic charge control, Ransburg systems consistently achieve transfer efficiencies above 97%. This allows businesses to significantly reduce paint consumption, minimize spray booth cleaning time, and maintain consistent speed and stability across the entire production line — all of which are critical to increasing productivity, reducing waste, and optimizing operating costs, especially in automated spray systems.

View productsCoature and Ransburg: Electrostatic Coating Technology Partners

Ransburg is a pioneering brand in the field of electrostatic spray technology, with over 80 years of development and continuous innovation. Ransburg equipment is renowned for its high transfer efficiency, precise control, and internationally recognized surface finish quality — meeting the stringent requirements of the automotive, electronics, and mechanical industries.

The partnership between Coature Vietnam and Ransburg brings modern coating solutions to Vietnamese customers that help reduce costs, minimize emissions, and increase production efficiency. We offer not only advanced equipment but also comprehensive support — from consultation and training to after-sales service.

With a long-term vision, Coature and Ransburg will continue to expand technical capabilities, enhance service quality, and work closely with customers to develop sustainable, efficient coating solutions that meet global standards.

Gallery

A: This service is designed to propose high-value-added Japanese paints to customers and efficiently deliver them to your doorstep.

A: Paint Voyager is a service that suggests high-value-added Japanese paints and enables efficient procurement even in small quantities.

A: We leverage our trusted relationships with Japanese paint manufacturers to efficiently source a wide range of paint products from Japan.

A: Yes, we offer a range of support beyond paints, providing various materials to help you achieve your coating requirements.

A: We have a fully-equipped hazardous material warehouse and comply with fire prevention regulations to safely store and supply hazardous materials, providing support for safe handling and procurement.